Background

Deutsche Bahn, abbreviated as DB, is a German railway company. Headquartered in Berlin, it is a private joint-stock company coming into existence in 1994, with the Federal Republic of Germany being its single shareholder. Deutsche Bahn describes itself as the second- largest transport company in the world, after the German postal and logistics company Deutsche Post / DHL, and is the largest railway operator and infrastructure owner in Europe. It carries about two billion passengers each year. Its railway line has been extended up to 34,000 km and there are 39,000 trains running each day. This brought new challenges for the railway's inspection work. Traditional way of routine inspection and maintenance has become unable to meet today's needs. It is in urgent need of more scientific means to improve the efficiency and quality of inspection work, thereby enhancing the company's overall operational level of service.

Challenges

-

The traditional railway track inspection needs to record information manually at the railway, and input this information on a computer back in the office, which is inefficient and error-prone.

-

The whole inspection process-from inspectors accepting inspection task to giving a final report- takes long time.

-

Real-time communication cannot be realized among inspectors, maintainers and administrators.

-

The administrators can't monitor the routine inspection in real time and can't be informed of the maintenance schedule.

Solutions

In response to user demands, Shenzhen Chainway Information Technology Co., Ltd. deployed C5000 handheld computers with 2D barcode scanning and UHF RFID functions to help realize intelligent rail tracks inspection and maintenance. Through handheld PDAs, maintainers can receive new task assignments in real time, give fault feedback, and report working conditions over wireless networks. It is of high accuracy and efficiency during the whole operation. At the same time, real- time communication and interaction among inspectors, maintainers and administrators can be realized.

Application Details

Task Assignment

Inspectors and maintenance men can receive new task assignments and specific requirements through the PDA.

Maintenance

Inspectors can input inspection results and maintenance men can record maintenance process and conditions in a timely manner.

Rechecking

The foreman and quality inspection team can carry the portable device to recheck and record the results on the PDA.

Data Management

Information can be shared in the railway management system that can plan the best inspection and repair route for working staff and automatically generate maintenance records.

Effects

-

It standardized and streamlined inspection and repair workflows.

-

These field workers can record information with a light-weight device in real time, which saved time and maximized productivity.

-

All data and information captured by inspectors, maintainers and administrators can be synchronized to the backend database. And then these data can be shared among them. In this way, they can communicate with each other better so that they can keep up with the newest status of each fault founded.

-

Handheld computers and fixed computers complement each other, working together to enhance the overall management level of this German railway company.

PDA Configuration

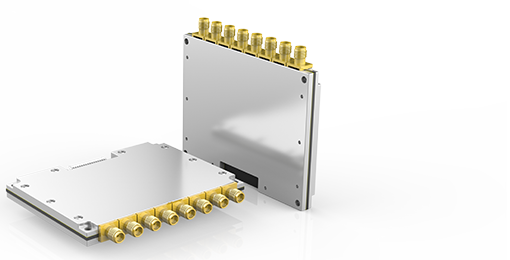

P/N: C5000

Functions: 2D, UHF RFID, Wi-Fi