During the daily operation and management in the traditional shoes and clothing industry, it is necessary to check the store and inventory items on a regular or irregular basis, such as daily, weekly or monthly, to check the store revenue, verify the inventory data, and adjust the product configuration. Due to the rich variety of shoes and clothing, the styles are diverse, it is difficult to check in a traditional manual way, which is a heavy workload and low efficiency for workers and it also is easy to make mistakes. Once the inventory data is wrong, there will be an embarrassing situation of re-counting, which is time-consuming and labor-intensive.

For example, when selling on-site, it is necessary to present the product size, color, discount information, etc., and the process is cumbersome, the response speed is slow, and the customer experience is poor. When inventorying goods, the inventory work is done by hand. Due to the wide variety of goods, the workload is large and often prone-error, resulting in inconsistencies between physical objects and accounting. The staff takes stock by manual. After they finish stock-taking, the data will be transcribed to the computer again, and the sales status cannot be timely reported to the manager or the headquarters. Moreover, the management of personnel is extremely inconvenient. As the member information cannot be synchronized, the members of each counter cannot be uniformly managed, which affects the consumer shopping experience.

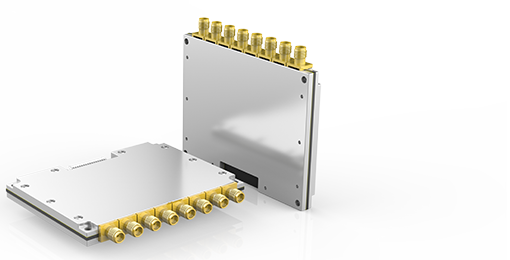

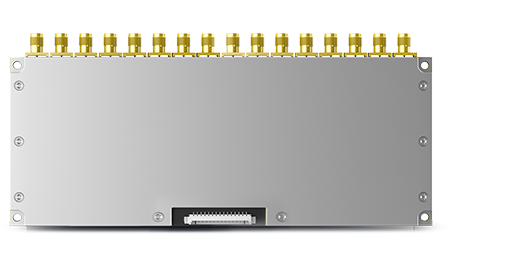

In view of the above problems faced by the shoe and clothing retail, Chainway launched an intelligent solution for the shoe and apparel industry. RFID technology is used to install RFID tags for each item that needs to be in stock. The inventory personnel can scan the goods barcode information by operating Chainway handheld terminal, then quickly complete the inventory of the goods. They can use the wireless data to transfer the product information to the back-end database, which is easy to realize accurate and intelligent stock-taking at any time.

Stock-taking: Through the intelligent PDA, it can achieve rapid stock-taking and efficient transfer of goods. The number of categories can be got at a glance, which greatly improves operational efficiency and supply chain feedback speed.

Intelligent shopping guide: Automatically identify clothing label information with PDA. Connect to the database system via WIFI, and obtain all the corresponding pictures and text information of the product in real time, responding to customer needs in the first time.

Sales management: Automatically count the sales of goods, including the types of products, specifications, sales volume, sales, etc., and upload the database system in real time via the network, which is convenient for managers to obtain sales information in real time.

It significantly improved the speed and accuracy of stock-taking in shoes and apparel industry. It realizes intelligent receipt and delivery, and eliminates manual operation. The accuracy of sorting has been greatly improved, which has promoted the high-speed operation of goods distribution; Managers can dynamically understand the front-end sales status and order data of chain stores in real time, which helps to make timely sales decisions, strengthen the unified management of each store and enhance the overall service quality and brand image.