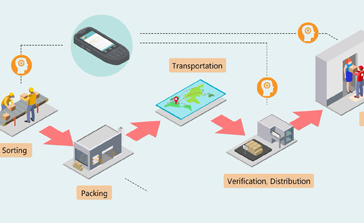

Challenges:

When an order needs to be picked for packing and shipping, traditionally warehouse workers pick those items from paper pick lists and based on directors’ voice instruments, then write down each transaction, and input those inventory changes into the ERP system via PC on a regular basis. Human mistakes may occur, delays may happen, and inventory data may be recorded inaccurately. Consequently, distribution centers or retailers cannot make data-driven marketing decisions.

Solution:

Chainway mobile computer receives electronic pick lists in real time from the backend server, generates a pick path based on the shortest path logic, scans products’ 1D/2D barcodes or RFID tags to make an automatic transaction verification, and sends the renewed inventory to the ERP system wirelessly (3G/4G/Wi-Fi).

Results:

1. All data are recorded electronically and transferred to the backend server wirelessly via Chainway mobile computer.

2. Pick lists are composed based on “shortest pick path” logic and assigned to the most suitable operators. It boosts productivity and efficiency.

3. Scanning products’ barcodes or RFID tags to make sure that the right item is picked from the right slot in before operators move them to the staging area.

4. After all the required stock has been taken from the warehouse slots, real-time inventory data is updated to the ERP system.

5. Knowing picking time, retailing stores can estimate the time of arrival of their wanted products and make instant marketing decisions.

When an order needs to be picked for packing and shipping, traditionally warehouse workers pick those items from paper pick lists and based on directors’ voice instruments, then write down each transaction, and input those inventory changes into the ERP system via PC on a regular basis. Human mistakes may occur, delays may happen, and inventory data may be recorded inaccurately. Consequently, distribution centers or retailers cannot make data-driven marketing decisions.

Solution:

Chainway mobile computer receives electronic pick lists in real time from the backend server, generates a pick path based on the shortest path logic, scans products’ 1D/2D barcodes or RFID tags to make an automatic transaction verification, and sends the renewed inventory to the ERP system wirelessly (3G/4G/Wi-Fi).

Results:

1. All data are recorded electronically and transferred to the backend server wirelessly via Chainway mobile computer.

2. Pick lists are composed based on “shortest pick path” logic and assigned to the most suitable operators. It boosts productivity and efficiency.

3. Scanning products’ barcodes or RFID tags to make sure that the right item is picked from the right slot in before operators move them to the staging area.

4. After all the required stock has been taken from the warehouse slots, real-time inventory data is updated to the ERP system.

5. Knowing picking time, retailing stores can estimate the time of arrival of their wanted products and make instant marketing decisions.